Gründe für die Auswahl eines Vier-Wege-Shuttles

Feb 17, 2025

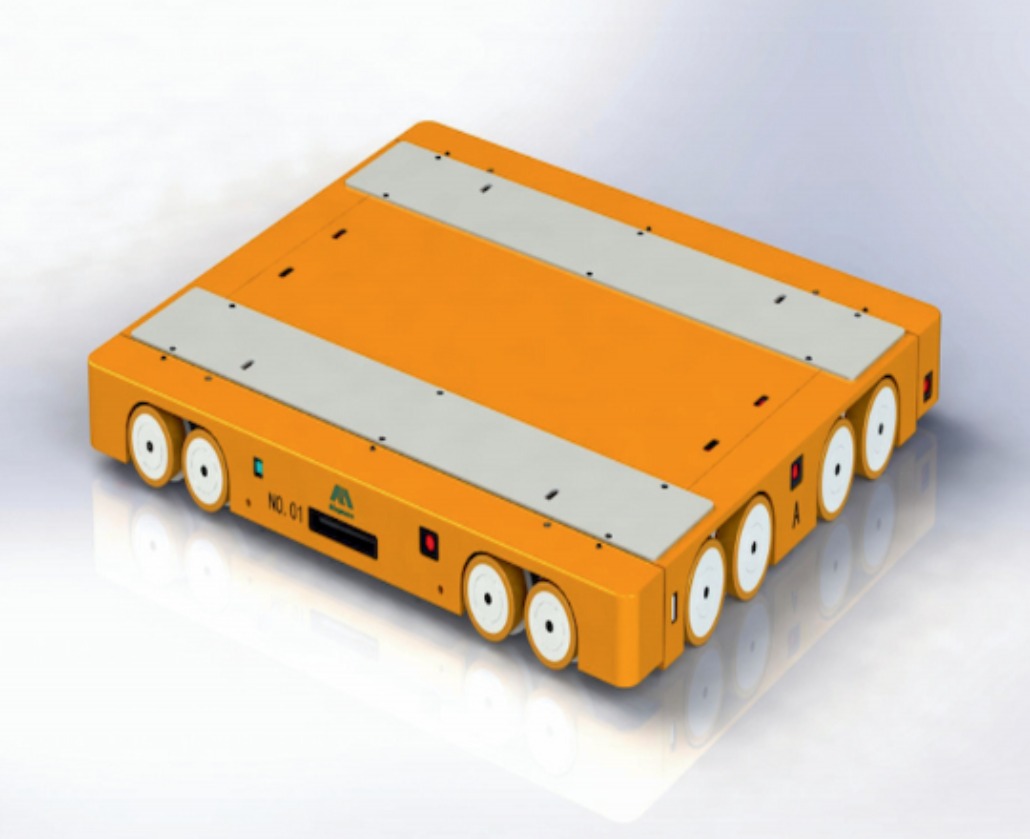

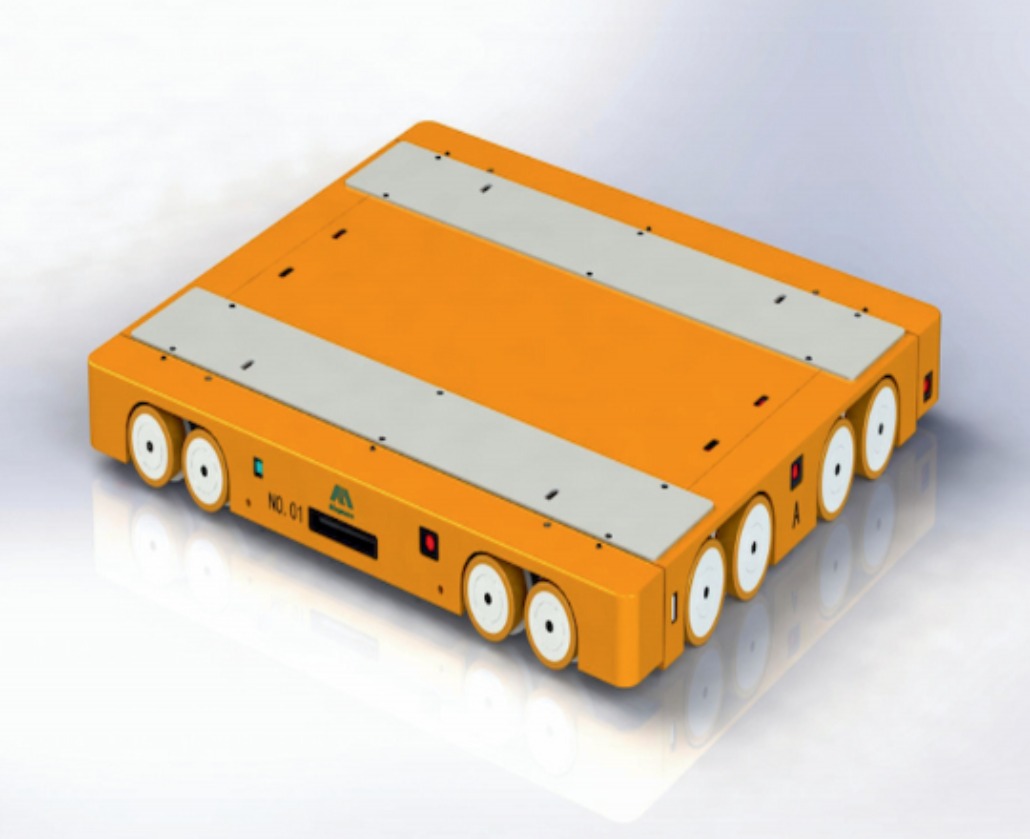

Ein Vier-Wege-Shuttle-System ist eine Art Staplerkransystem, das für die Umsetzung und Speicherung von Materialien in Lagern oder Verteilungszentren verwendet wird. Es bietet mehrere Vorteile, die es für viele Unternehmen zu einer beliebten Wahl machen. Hier sind einige Gründe für die Auswahl eines Vier-Wege-Shuttle-Systems:

- Vielseitigkeit: Ein Vier-Wege-Shuttle-System ist so konzipiert, dass sie sich in vier Richtungen bewegen: Vorwärts, rückwärts, links und rechts. Diese Flexibilität ermöglicht es ihm, über einen einzigen Gang mehrere Speicherspuren zuzugreifen. Es kann schmale Gänge und enge Ecken navigieren und einen beliebigen Standort innerhalb seines Betriebsbereichs erreichen, wodurch die Nutzung des verfügbaren Platzes maximiert wird.

- Hohe Speicherdichte: Das Vier-Wege-Shuttle-System kann sowohl in eintiefst- als auch in doppelt tiefgreifenden Speicherkonfigurationen betrieben werden, sodass Speicher mit hoher Dichte ermöglicht werden kann. Es kann auf mehrere Paletten auf einer Spur zugreifen und sie verarbeiten und die Speicherkapazität im Vergleich zu herkömmlichen Gabelstapler-basierten Systemen erhöhen.

- Erhöhter Durchsatz: Das Vier-Wege-Shuttle-System ist für eine effiziente und schnelle Palettenhandhabung ausgelegt. Es kann Paletten von beiden Seiten des Racks abrufen oder ablegen und gleichzeitige Operationen ermöglichen. Dies führt zu schnelleren Zykluszeiten und zu einem erhöhten Durchsatz, wodurch die gesamte Lagerproduktivität verbessert wird.

- Verbesserte Sicherheit: Das Vier-Wege-Shuttle-System ist mit fortschrittlichen Sicherheitsmerkmalen wie Sensoren und Kollisionsvermeidungssystemen ausgestattet. Diese Sicherheitsmechanismen helfen, Unfälle und Kollisionen mit Hindernissen zu verhindern und den Schutz sowohl des Personals als auch des Inventars zu gewährleisten.

- Automatisierung und Integration: Vier-Wege-Shuttle-Systeme können in Warehouse Management Systems (WMS) und automatisierte Steuerungssysteme integriert werden, die eine nahtlose Koordination und Kommunikation ermöglichen. Diese Integration ermöglicht Echtzeit-Inventarverfolgung, automatisierte Auftragserfüllung und effiziente Lagerbetrieb.

- Reduzierte Arbeitskosten: Durch die Automatisierung von Aufgaben zur Materialbearbeitung verringert ein Vier-Wege-Shuttle-System die Abhängigkeit von manueller Arbeit. Dies kann zu Kosteneinsparungen führen, indem arbeitsintensive Prozesse minimiert, Fehler reduziert und die Auslastung der Belegschaft optimiert werden.

- Skalierbarkeit: Das modulare Design des Vier-Wege-Shuttle-Systems ermöglicht Skalierbarkeit und einfache Erweiterung. Zusätzliche Shuttles können nach Bedarf hinzugefügt werden, um den wachsenden Speicheranforderungen eines Unternehmens gerecht zu werden.

Insgesamt macht die Kombination aus Vielseitigkeit, hoher Speicherdichte, erhöhtem Durchsatz, Sicherheitsmerkmalen, Automatisierung und Skalierbarkeit das Vier-Wege-Shuttle-System für Unternehmen zu einer attraktiven Wahl für Unternehmen, die ihre Lagerlager- und Materialhandhabungsvorgänge optimieren möchten.

NETZWERK UNTERSTÜTZT

NETZWERK UNTERSTÜTZT